Now their process recovers more than 97 of the rare earth elements. And Waseda University in Japan say they have started testing a jointly developed recycling process to recover rare-earth compounds from electrified vehicle motor magnets with the goal of enabling practical application.

Pdf Social And Environmental Impact Of The Rare Earth Industries

Office of Research and Development.

Rare earth recycling process. They found that the amount available for recycling could be at most 10 to 15 percent of the demand between now and 2015. The process itself involves heating a used motor to 1400 degrees Celsius approximately 2552 degrees Fahrenheit so that it melts down. The UK has no domestic source of primary rare earths.

The two companies are now working on a way to practically integrate this process in electric vehicle recycling activities. National Risk Management Research Laboratory. EPA Region 7 Kansas City Kansas.

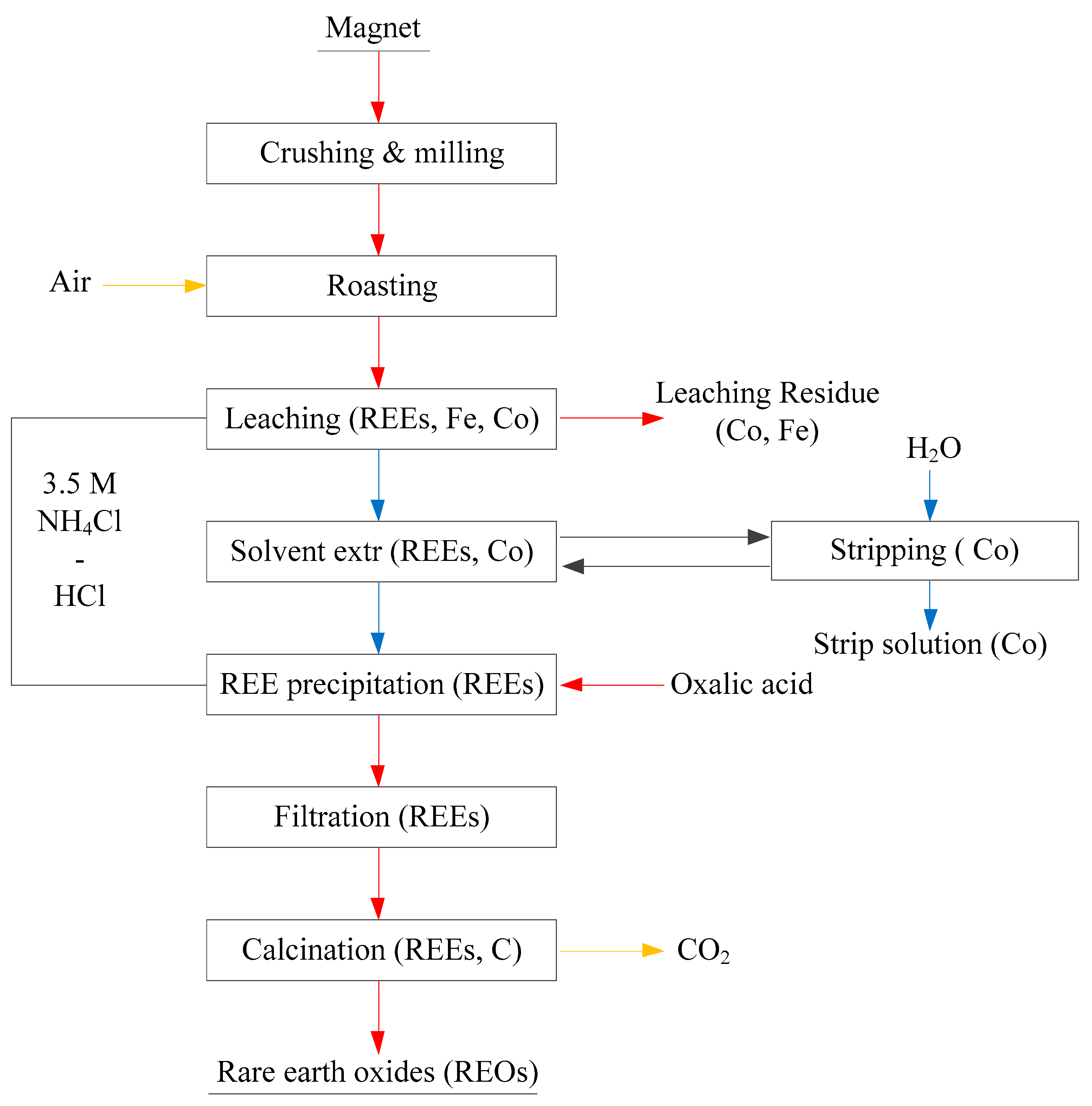

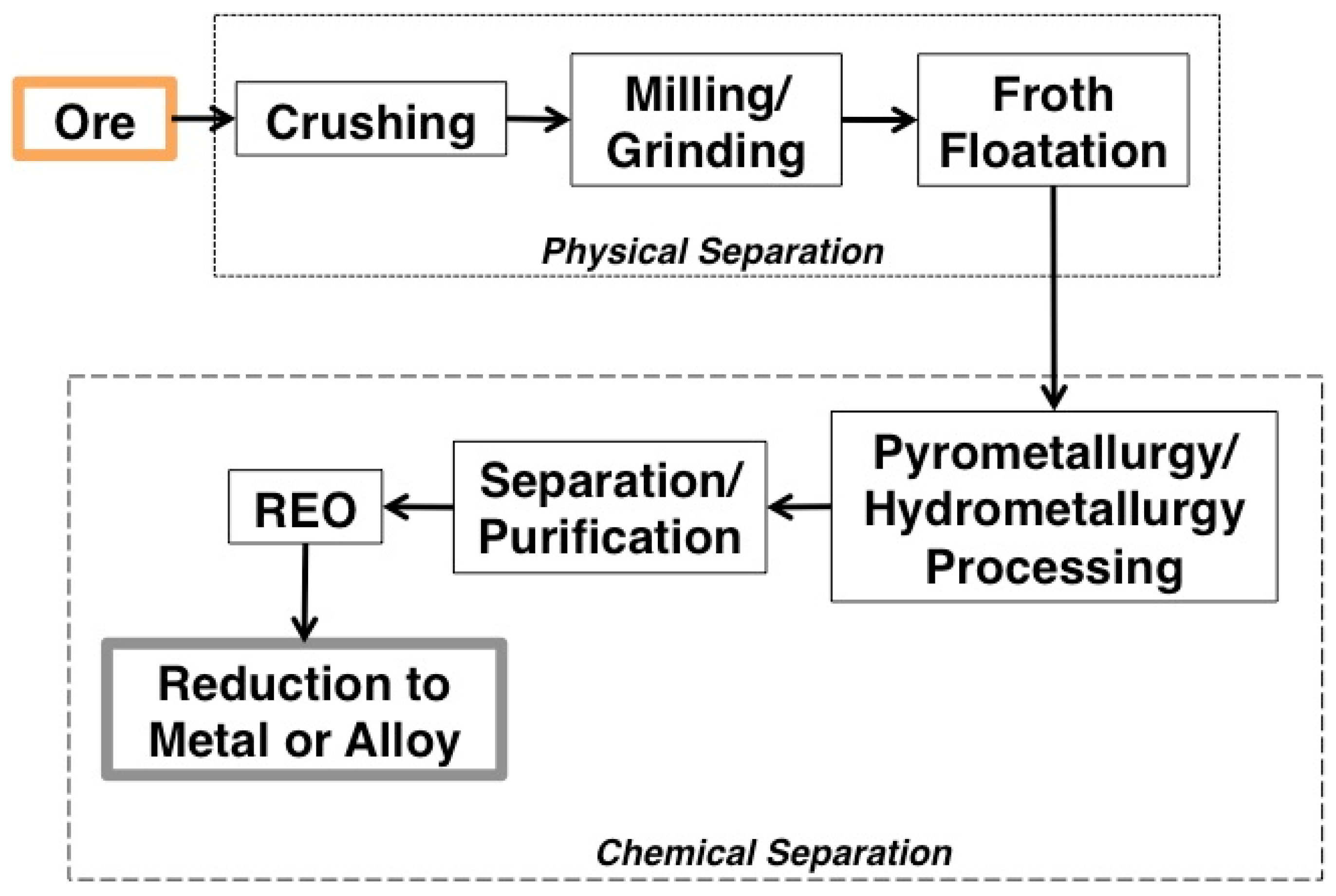

Nissan develops new rare-earth recycling process with Waseda University - YouTube. In these processes hazardous substances such as REEs-containing dust metals and chemicals were used or occurred including the risk of ignition and explosion and the workers can be easily exposed to them. Through a process of crushing milling conditioning and flotation the rare earth elements in the ore are separated from the other elements forming a rare earth concentrate.

A Review of Production Processing Recycling and Associated Environmental Issues. Scientists at the Critical Materials Institute have developed a two-step recovery process that makes recycling rare-earth metals easier and more cost-effective. This recycling process combines the capabilities of Umicores proprietary Ultra High Temperature UHT battery recycling process with Rhodias rare earth refining competences.

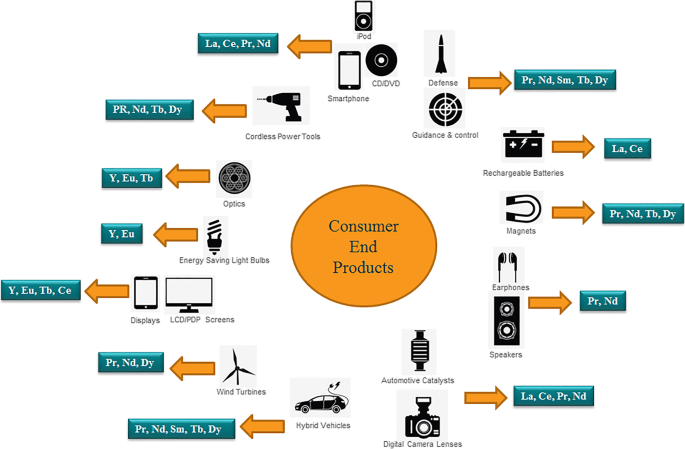

The supply issue of rare earth elements REE has become an increasingly important issue both economically and politically. The patented process recovers more than 97 of the rare earth elements from scrapped magnets at purities exceeding 995 by weight. Their industrial importanc e continues to increase while most.

Office of Science Policy. Solution studies revealed that the early rare earth compounds. In one recent study Jelle Rademaker of the Green Academy in the Netherlands and colleagues calculated the potential for rare earth recycling from magnets in computer hard drives hybrid cars and wind turbines assuming 100 percent recovery in each case.

Recently a group of researchers from the University of Pennsylvania discovered a separation process that could make purifying recycled rare earth elements much less expensive. The development of domestic sources of recycled rare earths via HPMS Hydrogen Processing of Magnet Scrap a homegrown technology is a significant opportunity for the UK to fast-track the development of sustainable and competitive rare earth magnet production. The concentrate undergoes a complex chemical process to purify recover separate and precipitate the individual rare earth elements.

5 Global rare earth processing 25 51 Rare earth processing in China 25 511 Production statistics 25 512 The Chinese policy concerning the rare earth processing industry 30 5121 Entry criteria for rare earth industry 30 5122 The 2009-2015 plans for developing the rare earth industry 31 52 Rare earth processing outside of China 32 6. The rare earths can be recovered from the boron trioxide glass slag by first dissolving the glass slag in sulfuric acid followed by selective precipitation of the rare earths as a sulfate double salt or a hydroxide Saito et al 2006. Nissan is also recycling REEs by removing magnets from motors that do not meet.

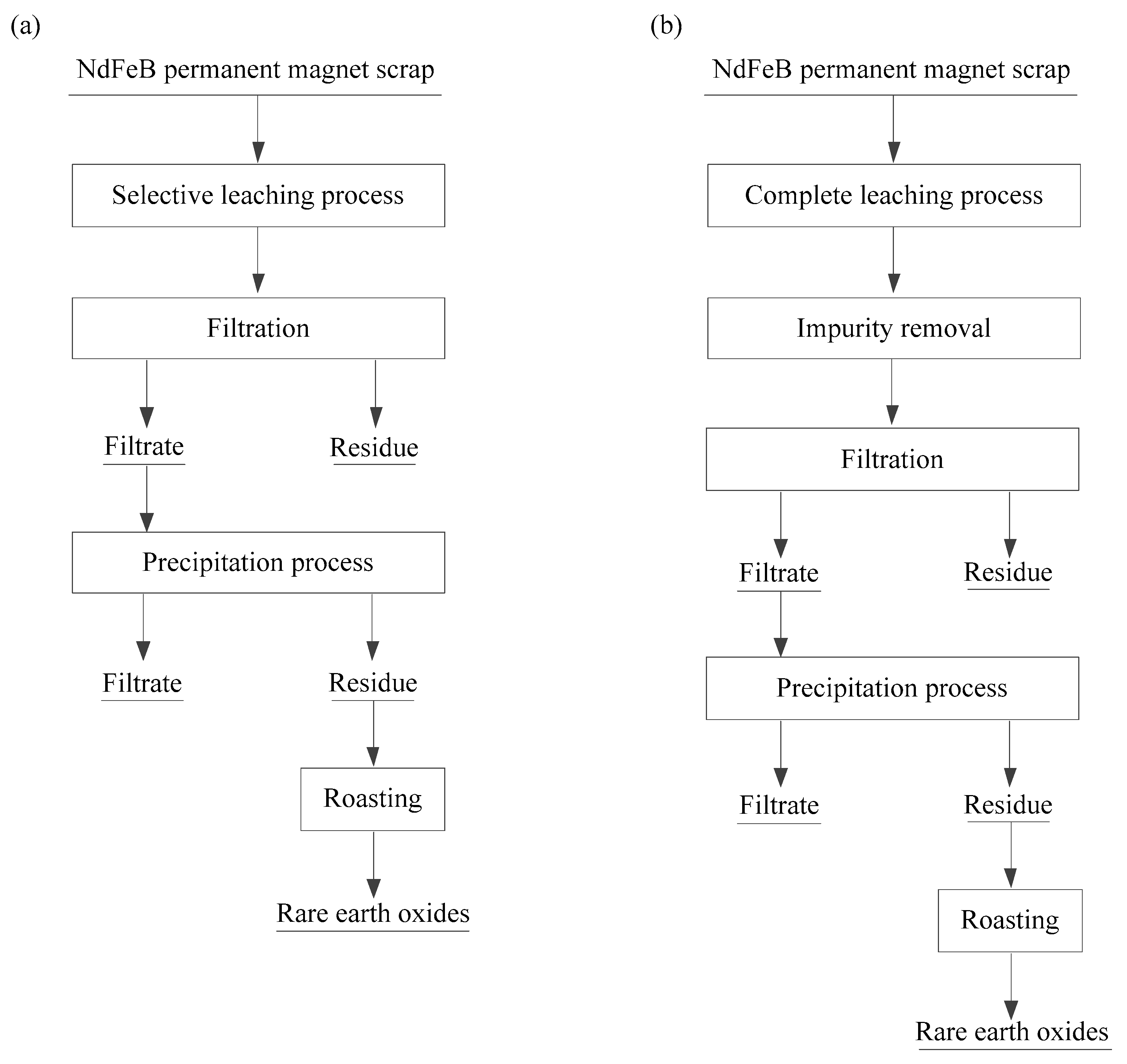

These large-scale recycling processes are either hydrometallurgical processes similar to. REE recycling has four key steps such as collection dismantling separation and processing. Director Engineering Technical Support Center.

EPA Office of Research and Development. For example to remove an NdFeB magnet contained within a computer hard disk drive would require the removal of 8-10 security screws and the magnet is glued in placed and coated in Ni. The company then adds an.

Since 2010 Nissan has been working from the design stage to reduce the amount of heavy rare-earth elements REEs in motor magnets. Nissan and Waseda University found that this process was able to recover up to 98 of the rare earth elements in each recycled motor while cutting down the time taken by 50. Weber Superfund and Technology Liaison.

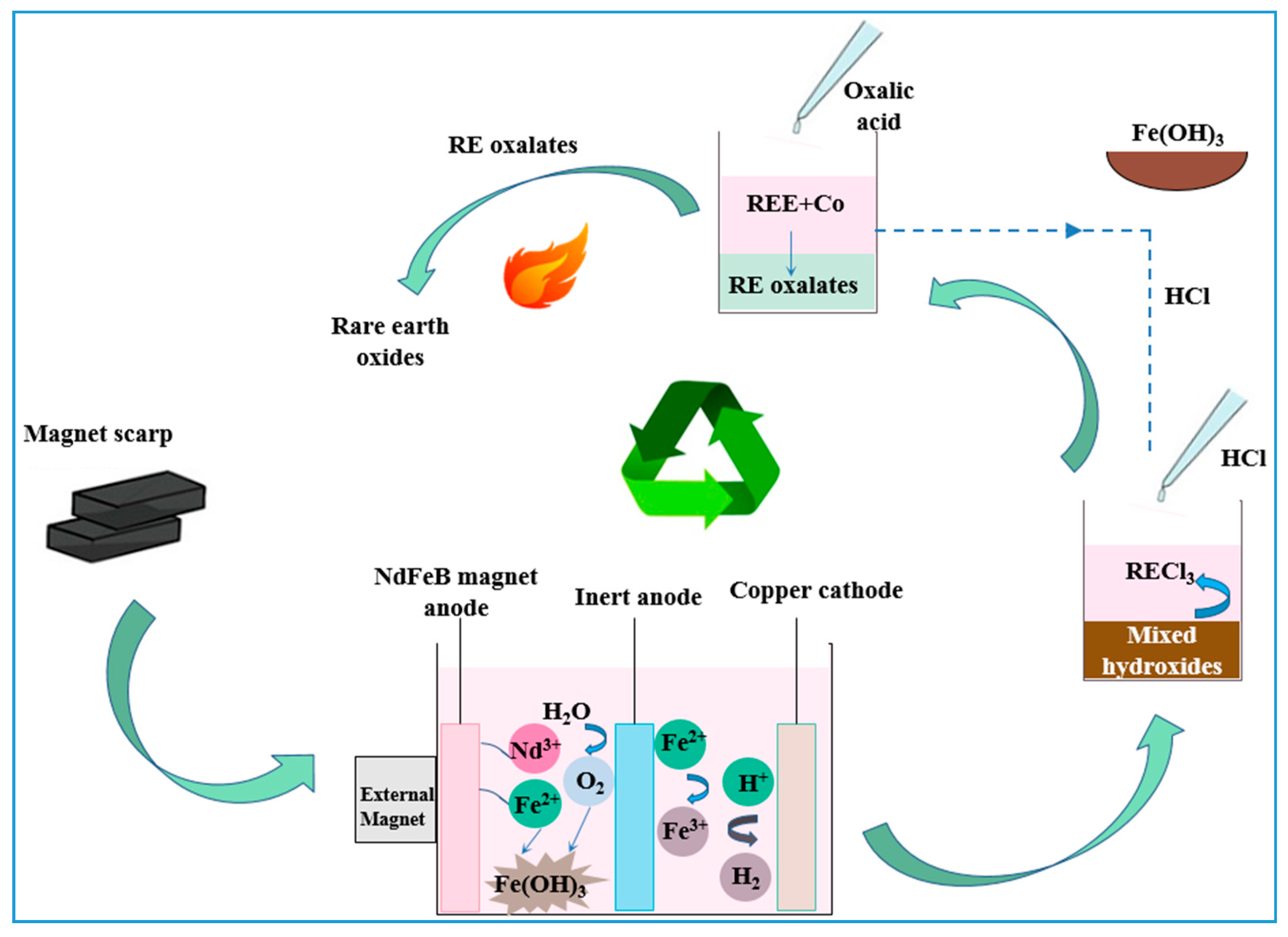

To d ate Bhaves recycling project has resulted in a patent and two publications here and here documenting recovery of three rare earth elementsneodymium praseodymium and dysprosiumas a mixture of oxides. The metal is extracted by an electroplating process which deposits the rare earths onto the cathode and electrorefming where the anode is composed of the recycled materialwhen the current passes from the anode to the cathode through the acidic electrolyte the anode corrodes releasing the rare earth. A Review of Production Processing Recycling and Associated Environmental Issues Robert J.

Electrometallurgy processes such as electrowinning where a current is passed from an inert anode through a liquid leach solution containing the metal. Land Remediation and Pollution Control Division. Today very little rare earth material is recycled which is partly due to the technological difficulties in separating magnets from waste streams.

Nissan and Waseda University are testing a jointly developed recycling process that recovers high-purity rare-earth compounds from EV motor magnets. By developing a new organic compound H 3 TriNOx for binding rare earth cations this group formed 15 different rare earth compounds. Engineering Technical Support Center.

The process recovers high-purity rare-earth compounds from motor magnets the partners say. Automaker Nissan Nissan Motor Co. Based in Montreal Geomega Resources has developed a rare earth separation technology ISR that recycles rare earth elements with a focus on the permanent magnet industry and produces four high demand high price rare earth elements HHREE - specifically neodymium Nd praseodymium Pr terbium Tb and dysprosium Dy.

More developed nations are less willing to accept the. The process generates vast amounts of toxic and radioactive liquid waste resulting in extensive environmental degradation and plenty of health hazards for those working the mines and processing facilities which goes some way to explaining Chinas dominance of the rare earth scene. Umicore and Rhodia have jointly developed a unique process for the recycling of rare earth elements REE from Nickel Metal Hydride NiMH rechargeable batteries.

The REEs are then recovered from the slag.

Pdf Social And Environmental Impact Of The Rare Earth Industries

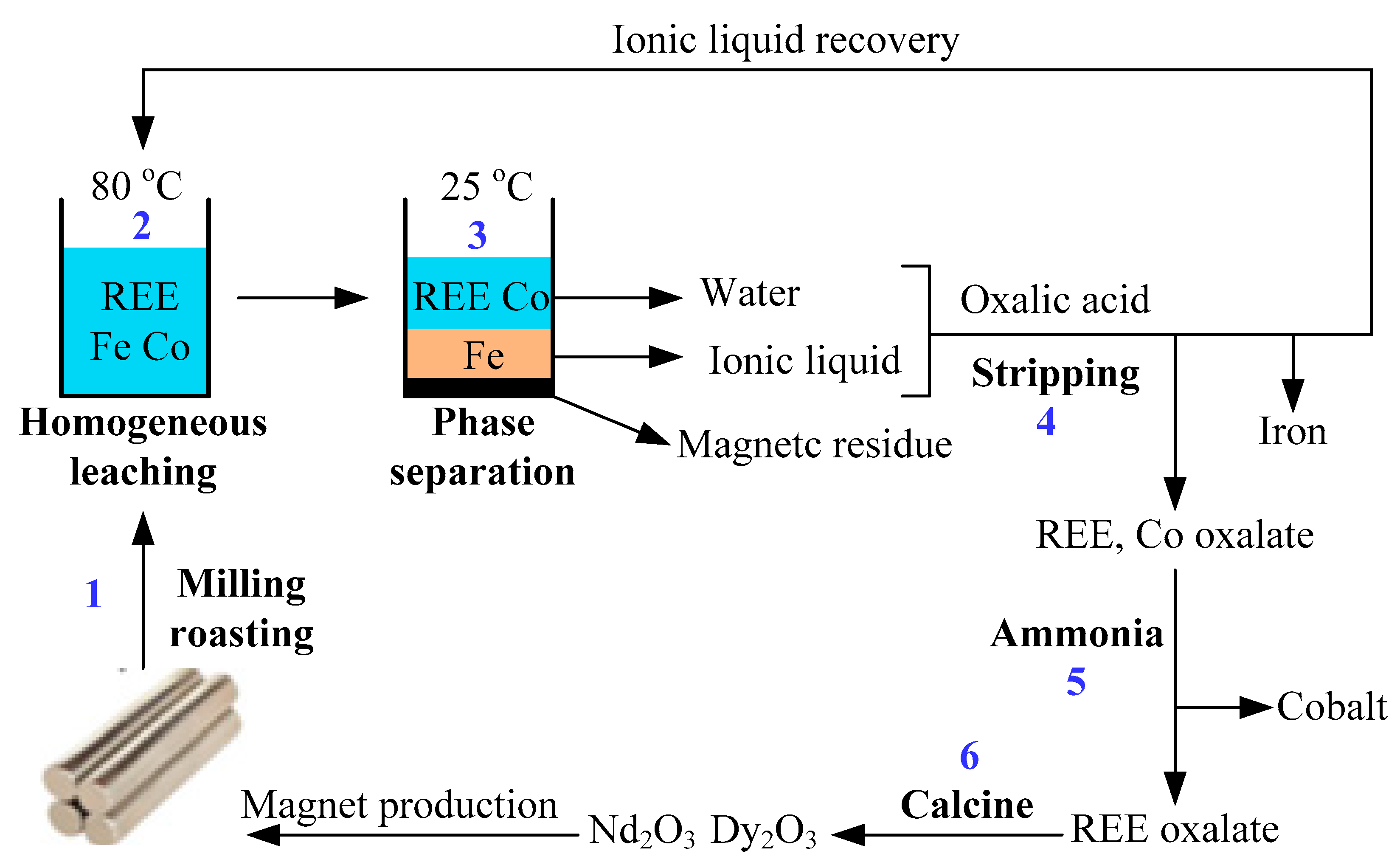

Solvometallurgical Process For The Recovery Of Rare Earth Elements From Nd Fe B Magnets Sciencedirect

Recovery Of Rare Earth Elements From Waste Streams Using Membrane Processes An Overview Sciencedirect

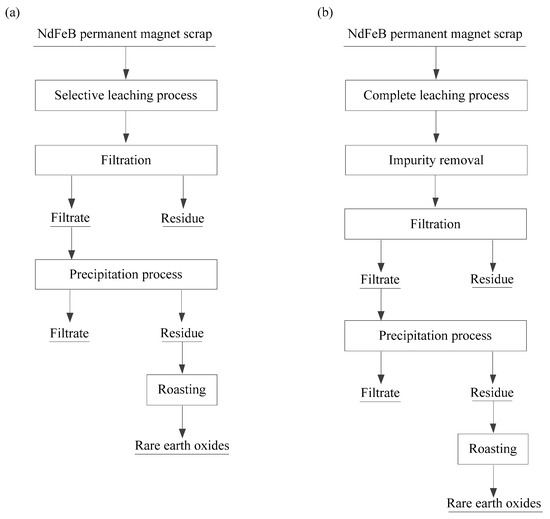

Metals Free Full Text Hydrometallurgical Recovery Of Rare Earth Elements From Ndfeb Permanent Magnet Scrap A Review Html

Canadian Firm Secures Exclusive Rights To Purdue S Rare Earth Element Separation And Purification Technology A 4 Billion Global Market Purdue University News

Metals Free Full Text Hydrometallurgical Recovery Of Rare Earth Elements From Ndfeb Permanent Magnet Scrap A Review Html

Review Of Rare Earth Elements Recovery From Secondary Resources For Clean Energy Technologies Grand Opportunities To Create Wealth From Waste Sciencedirect

Recycling Nickel Metal Hydride Batteries Onda Finds Way To Recycle Nickel Metal Hydride Batteries Used In Hybrids Honda Has Established The Reuse Rare Honda

Recovery Potential Of Rare Earth Elements From Mining And Industrial Residues A Review And Cases Studies Sciencedirect

Pdf Recovery Of Rare Earths From Industrial Waste Residues A Concise Review

Resources Free Full Text On The Extraction Of Rare Earth Elements From Geothermal Brines Html

Metals Free Full Text Hydrometallurgical Recovery Of Rare Earth Elements From Ndfeb Permanent Magnet Scrap A Review Html

A Review Of Rare Earth Elements Extraction With Emphasis On Non Conventional Sources Coal And Coal Byproducts Iron Ore Tailings Apatite And Phosphate Byproducts Springerlink

Metals Free Full Text Hydrometallurgical Recovery Of Rare Earth Elements From Ndfeb Permanent Magnet Scrap A Review Html

Metals Free Full Text Hydrometallurgical Recovery Of Rare Earth Elements From Ndfeb Permanent Magnet Scrap A Review Html

Selective Extraction And Recovery Of Rare Earth Metals From Waste Fluorescent Powder Using Alkaline Roasting Leaching Process Sciencedirect

Why Rare Earth Recycling Is Rare And What We Can Do About It Ensia

Reclaiming Rare Earth Elements From End Of Life Products A Review Of The Perspectives For Urban Mining Using Hydrometallurgical Unit Operations Sciencedirect

Simplified Flow Sheet Of The Umicore Battery Recycling Process With Download Scientific Diagram

No comments:

Post a Comment